High-performance kilning plants

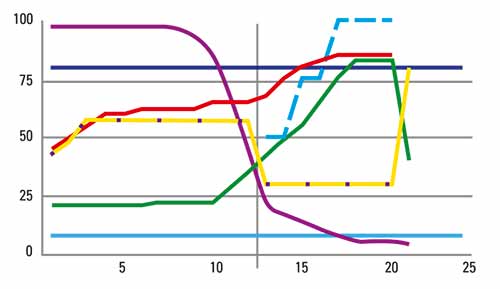

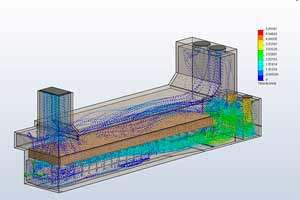

Kilning plants designed and manufactured by Rauscher Engineering ensure a high degree of energy efficiency, gentle processing and low-maintenance as well as meeting high hygienic standards. Our experience in the field together with special software enable savings in energy consumption due to the calculation of optimized air flow and the implementation of high-performance equipment.

State-of-the-art kilning plants can either serve as high-performance single-deck kilns or double-deck kilns with a reversible air-flow system.

Circular high-performance kilns

Rotating floor

State-of-the-art kilns with a rotating floor comprise the following:- Rotating floor structure with ring beams, girders and floor drive (Patent)

- Mesh floors with wedge wire sieves ore perforated sheets

- Fixed loading and unloading unit

- Discharging system in the vessel wall

Fixed floor

tate-of-the-art kilns with a fixed floor comprise the following:- Substructure for the mesh floor

- Mesh floors with wedge wire sieves ore perforated sheets

- Rotating loading and unloading unit

- Energy supply (e.g. slip ring)

- Rails and racks for the rotating machine

- Discharging system in the center

Rectangular kilns

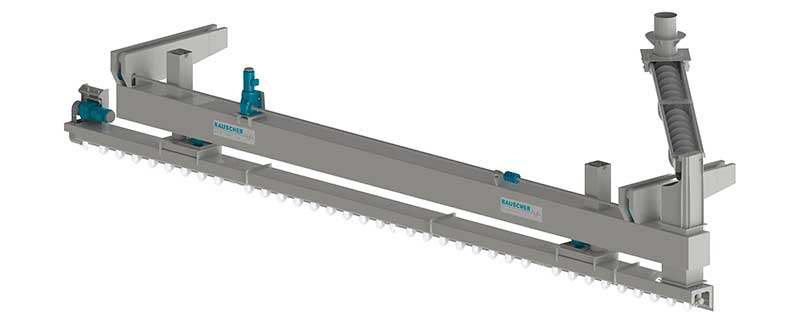

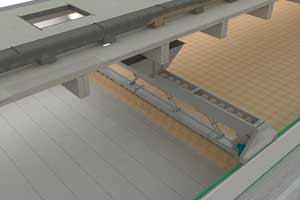

Rectangular kilns

Equipment for existing or new kilns:- Dumping floor with substructure, mesh floor and lifting drive

- Loading unit for supplying the kiln automatically

Kilning plant equipment

Kilning plant equipment

- Conveyors for the gentle transport of green malt e.g. chain conveyors, belt conveyors, screws and bucket elevators

- Aerodynamic air ducts for air supply, exhaust and recirculation

- High-performance fans for withering and curing

- Cross-flow heat exchanger for heat recuperation

- Indirect air heater, e.g. heater with gas/oil burners or hot-water coils

Images